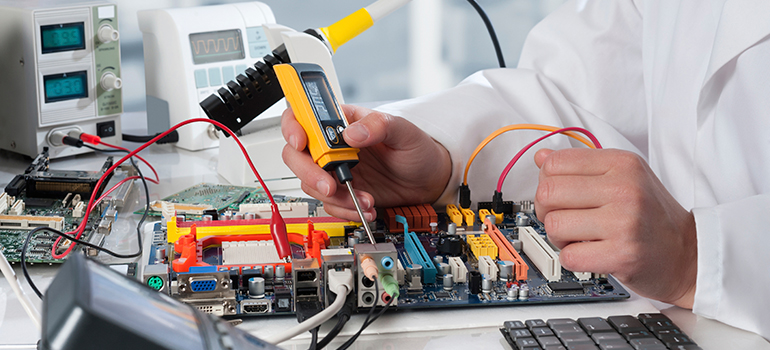

Forensic Engineering - Machinery and Equipment Breakdown

Machinery and equipment breakdowns cause costly disruptions to business operations. Intertek’s forensic engineering team investigates the causes of machinery and equipment breakdowns for all industry sectors.

Clients for our forensic engineering investigation Total Quality Assurance services include equipment owners and operators, insurance claims professionals and attorneys (liability and subrogation). Not only can Intertek’s multidisciplinary team of forensic investigators and engineering experts determine root cause failure of machinery and equipment breakdown, but they can also provide litigation support, including technical consultation and expert witness testimony.

Our machinery and equipment breakdown services include:

- Equipment condition assessment, including documentation of pre-existing damage, by site walkdowns, non-destructive examination and plant personnel interviews.

- Assessment of damage caused by the breakdown, including sequence of damage.

- Origin and cause including failure mode and root cause using:

- Design and material verification

- Stress analysis

- Fracture mechanics analysis

- Heat transfer and fluid mechanics analysis

- Thermal-hydraulics analysis

- Run/repair/retire decisions

- Scope and cost of repair, including audit of repair quotes

- Oversight of repair contractors

The types of equipment we have worked on include, but are not limited to, the following:

| Electric utility boilers | Pumps |

| Package firetube and watertube boilers | Heat recovery steam generators |

| Fluidized bed boilers | Mechanical seals |

| Industrial furnaces | Piping |

| Valves | Industrial water heaters |

| Petrochemical processes | Food process equipment |

| HVAC | Oilfield equipment |

| Burners | Transformers |

| Circuit breakers | Atmospheric above-ground tanks |

| Conductors | Pressure vessels |

| Steam and combustion turbines | Cables |

| Switches and relays | Generator rotors |

| Metal-clad switchgear | Fin-tube heat exchangers |

| Fans | Motors |

| Lighting equipment | Welded and bolted structures |

Coming Soon: Case study examples of types of machinery and equipment breakdown that we have analysed in our forensic engineering practice:

- Ammonia-based evaporator in a cold storage warehouse

- Cyclone separator in a mining operation

- Damage to a steam turbine in a paper mill

- Delayed coker accident in a refinery

- Diesel engine wear out

- Electrical generator rotor fractures

- Electrical generator stator failure

- Gantry crane damage by utility power plant fire

- Hydroelectric turbine bearing failures

- Insulation panels in mushroom-growing plant

- Nuclear power plant component fractures

- Ore drying equipment overheating

- Paper mill equipment freeze damage

- Power Plant Cave-in

- Stationary diesel engine damage

- Steam turbine blade erosion and corrosion

- Steam turbine rotor blade failure

- Textile carding machine malfunction

- Turbine speed reduction gear malfunction

- Turbine-generator over-speed damage investigation

- Water treatment plant structural collapse

Need help or have a question?