Heat Recovery Steam Generator Inspection

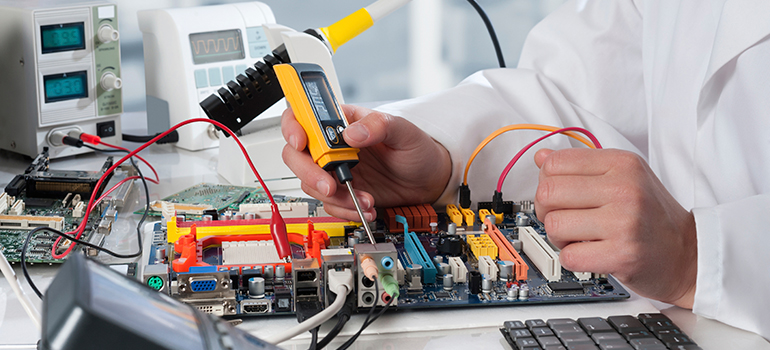

Visual inspection, in combination with analytical devices, provides condition assessments needed to ensure that Heat Recovery Steam Generator’s (HRSG) operate safely and efficiently.

Annual visual inspections of HRSGs can reveal important details about the condition of components, including insulation damage, external tube damage, through-wall corrosion and fouling. With these details alone, many critical actions can be recommended by a knowledgeable engineer.

However, thorough condition assessment requires more than just a visual inspection as internally damaged mechanisms could still be present. Unit age, duty cycle and design determine the risk and severity of these mechanisms. Intertek’s Asset Integrity Management (AIM) Total Quality Assurance engineering team has the technology needed to fully assess the condition of HRSGs and provide engineering analysis to assist you in making technically sound decisions for the health of your equipment. Some examples of analytical devices include:

Through-Fin Inspection System for HRSGs - A pulsed eddy current device detects wall thinning in finned tubes which may signal flow-acceleration, under-deposit, or dew point corrosion mechanisms.

Ultrasonic Thickness and Deposit Measurement – For unfinned tubes, we can obtain a quantitative measurement of deposit loading and wall thickness, allowing our team to make reliable calculations of a component’s remaining useful life.

Metallurgical Sampling – This destructive test, when selectively and intelligently deployed, provides in-depth information about what may be happening within the HRSG. When several potential damage mechanisms are indicated, arriving at the correct conclusion and choosing the right course of action is important to save time and cost by minimizing repeat failures and protecting the long term health of the unit.

Intertek’s AIM engineering team assesses the individual risk factors for a site, plans and executes an effective and timely visual/non-destructive testing (NDT)/metallurgical inspection, and provides full documentation of component condition as well as disposition any findings with economic and technically sound recommendations.

Intertek's HRSG services include:

Need help or have a question?