Oil Condition Monitoring (OCM)

Global Oil Condition Monitoring (OCM) or Used Oil Analysis (UOA) support, where and when you need it, in order to protect your valuable assets and minimise risk.

Oil Condition Monitoring (OCM) or Used Oil Analysis (UOA) predictive maintenance programmes help clients avoid costly machinery, engine and power-train failures by tracking changes in machinery lubricant quality. Providing vital ‘early-warning’ of impending problems and supporting smooth and reliable machinery operation.

Operational issues in machines, engines and other components are often reflected in the condition of the lubricant oil being used. Regularly scheduled oil condition monitoring or used oil analysis can identify mechanical problems before they impact the efficient running of machinery, avoiding costly headaches later on.

Lubricants have to work under demanding conditions, exposed to constant high pressures, temperatures and other harmful factors, including water contamination, corrosion, fuel, and air ingested particles. High levels of wear particles give advance warning of possible machinery malfunction, allowing early remedial action to be taken. Where analytical results suggest no undue wearing is taking place, the operator may extend the interval between services or oil changes.

Scheduled lubricant testing and expert advice can avoid and mitigate costly component or system failures and unscheduled maintenance.

How we can fulfil your Oil and Lubricant Analysis Quality Assurance needs

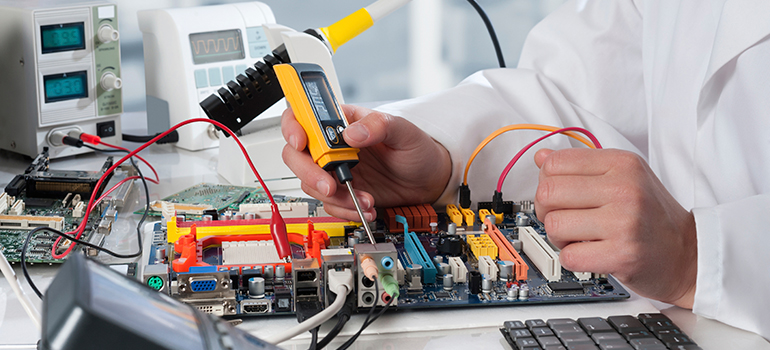

Our OCM or UOA programmes measure engine oils, lubricating oils, and other fluids for the detection of mechanical wear, lubricant quality degradation, and other associated issues.

Operating on a global basis in 24 locations around the world, our oil condition monitoring or used oil analysis laboratories offer accredited oil and lube testing results, presented in easy-to-read and understandable reports. We provide customised and extensive analysis test suites and packages, including tests such as elemental analysis, viscosity, dilution, water detection, acid number, base number, particle counting, and particle analysis to name a few.

Our testing capabilities cover a vast range of oils and lubricants, spanning a range of industries and sectors including; diesel engine lubricants, gas turbine generators, gearbox oils, gas engine oil, jet engine oil testing, hydraulic fluid, brake fluid, grease testing, transformer oil testing, petrol, metalworking fluids, greases and gasoline engine fluids.

Online access to results 24/7

Our customised solution includes reports sent directly to your nominated contacts and/or access to our online portal. Our portal (Interlink) enables our customers to easily review data including:

- The number of samples sent in for testing in a specified time period

- The number of normal, caution or warnings

- Data analytics including drill downs and management reports

- Exporting of data and trending

Global OCM programmes carried out by our team of experts

Our Oil Condition Monitoring or Used Oil Analysis programme will assess your fluid for problems and report these issues quickly and efficiently. Tests are performed in state-of-the-art Intertek laboratories by fully qualified chemists. The OCM analysis results are reviewed by our experienced analytical data specialists to indicate oil and machinery health.

Using our Intertek OCM or UOA programme is easy and cost-effective. By using Intertek to routinely test and check the condition of your machinery lubricating oils, you receive valuable comprehensive reports on both the condition of the lubricating oils and their machinery. We develop individual testing programmes to meet your Total Quality Assurance needs and ensure sample collection, shipping, testing and reporting is seamless, efficient, and cost-effective.

Intertek’s oil analysis expertise provides our clients with a multitude of benefits, with world-class testing facilities and global service coverage. Our independent and impartial Total Quality Assurance specialists can truly satisfy your requirements with the precision, pace and passion you desire.

Wear debris is generated within any rotating system. By analyzing the debris OCM provides clients with a picture on the condition of their systems and where the debris may have originated from within systems, allowing informed decisions to be made on servicing and potential concerns to be addressed.

Intertek Caleb Brett have utilised cutting edge Scanning Electron microscopy in an innovative way to provide condition monitoring services to clients with unprecedented accuracy.

SEM is a very powerful analytical tool and well suited for wear debris analysis as part of an OCM programme. The technique provides highly detailed morphological and compositional information on debris allowing highly accurate conclusions on the health of assets to be made. SEM sample analysis can be automated meaning samples can be analysed quickly as well as accurately to provide semi-quantitative results.

The SEM technique can be used to quantify and characterize a wide range of samples including:

• Oil, fuel and hydraulic fluids

• Magnetic plug debris

• Grease analysis

• Patch test analysis

• Fuel/oil filter debris analysis

Intertek has extensive experience and expertise in providing wear debris analysis to clients, having operated the service for over 40 years with applications covering a vast range of sectors including defence, aerospace, marine and renewable energy.

Lubricant and oil condition monitoring testing:

Factsheet: Wear Debris Analysis

TransoilCHECK Services

TurbineCHECK Services

AeroCHECK Services

Need help or have a question?

- APAC:

- +65 6805 4800

- Australia:

- +61 1300 046 837

- Netherlands

- +31 88 126 8702

- Belgium

- +32 3 543 9089

- Brazil:

- +55 11 2322 8033

- China:

- 400 820 5033

- +86 21 6485 5558

- EMEA - UK:

- +44 1708 680 200

- FR:

- +33 2 35 13 41 00

- Germany:

- 0800 5855888

- +49 711 27311 152

- India:

- + 91 22 4245 0100

- Italy:

- +39 02 95383833

- Mexico:

- 01 800 5468 3783

- +52 55 5091 2150

- Spain:

- +34 902 377 388

- UAE

- +971 4 317 8777

- S Africa:

- +27 010 900 4411

Ordering OCM tests in the continental United States?

Order test kits online.Oil Condition Monitoring Services

Caleb Brett News and Events

Case Study: Wear Debris analysis on Marine Cargo Ships Download now

Whitepaper - Tank Calibration using Laser Scanning Technology Download Now

Case study - Wear Debris Analysis Using Scanning Electron Microscopy: Download now

Webinar - Wear Debris Analysis as a Condition Monitoring Tool: Download our On Demand Webinar

Webinar - REACH Testing: Petroleum UVCBs – analysis for dossiers: View the Webinar

Caleb Brett Brochure - Cargo Inspection & Analytical Assessment Services

Caleb Brett Brochure - Cargo Inspection & Analytical Assessment Services

Download our Brochure

-2021.jpg?n=5267)