STC Ratings: Six Things You Never Knew

22 Mar 2022

It's important to understand the nuances of sound transmission class ratings and how they relate to real-world noise control options

While originally developed for speech privacy, sound transmission class (STC) ratings have become a standard of design for spaces where acoustics are a concern and the most common sound reduction measurement in use today.

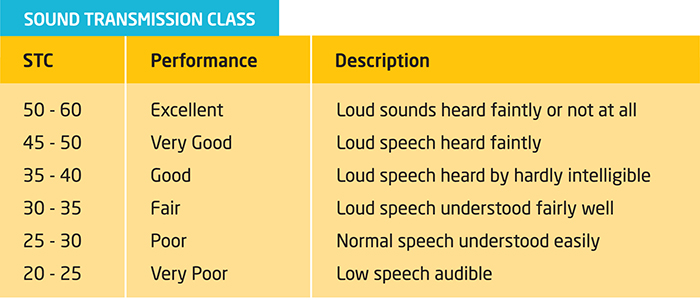

Simply put, STC ratings measure sound level on one side of a wall, versus the other side of a wall. However, architectural acoustics can often become a bewildering array of alphabet soups (STC, OITC, and IIC, to name a few!), and even acoustically experienced architects and designers can be left scratching their heads. Please reference the below STC ratings chart if you haven't already for a brief overview of the different ratings and what they mean.

Six Things You Never Knew About STC Ratings

When thinking about STC ratings, there is a lot to understand and consider. There is plenty of information out there at our fingertips, but it's important to get a full picture. Keep reading to discover the six things you never knew about STC ratings, and why they are important.

1. Products versus Spaces

Both products and interior spaces can have STC ratings, but there are important differences. A room is rated on the "sum" of the products used to create each partition or floor/ceiling assembly. If a wall includes a window and some HVAC vents, it may have a very different rating than a wall with no punched openings. So, if one is using a window's STC 35 rating, but the wall panels are rated at 45, the total wall calculations may be different. The final STC rating of a room is a composite, not an individual component calculation.

Product ratings are also essential. For example, the STC number provides a standardized way to compare products such as doors, windows, or wall panels made by competing manufacturers. A higher number indicates more effective sound insulation than a lower number. Without these ratings, product selection becomes more difficult as overall space design is considered.

2. Frequency Matters

Our world is a noisy one, and new technology has produced sounds that are literally off the STC charts. STC ratings have a cutoff of 125 Hz, but there are sounds below that level. Think: transit systems, pounding bass music from a PowerPoint presentation in the next room, explosions, or even a colleague with a booming voice. While a space may have a perfectly acceptable STC rating, there will inevitably be intrusive noises that "leak" in a room.

A coincidence dip is a weakness at a specific frequency. This occurs when a material (commonly glass) vibrates or resonates at the same frequency as the source of the noise. Essentially it is a frequency range in which glass has a greater transparency to sound waves. When even a high-performance window has a weakness at a specific frequency, there may be certain sounds, such as a siren that penetrate the window.

Designers and owners who have met code (or self-imposed requirements) are often unhappy when the complaints come in. There are many sound masking strategies to alleviate these problems and here is where good communication about the space usage comes in. If a high-rise about to be constructed next door to a project, now is the time to talk about potential noise concerns.

3. The Weakest Link

Outside high-frequency noise can be a huge problem, but inside a space, the way the partition or floor/ceiling assembly is constructed can have a powerful impact on the room's acoustic balance. Different sound transmission paths – over the wall, under the floor, etc. – go into STC rating. Windows in a wall might be a 45, but the door may be 30. Your weakest link will be the door and the design should be controlled by the weakest link. Wall construction and products all come into play.

The weakest link can manifest itself in different ways. For example, sometimes, re-treating the room with added products can be helpful. Designing toward the weakest link is essential for sound proofing success.

It is important to note that an STC rating should not be the sole basis on which a decision to use a particular construction is made.

4. De-Constructing Construction Methods

There are many ways to improve the sound transmission class of a partition or floor/ceiling assembly though the two most basic principles are adding mass and increasing the overall thickness. In general, the sound transmission class of a double wall (e.g., two 4-inch thick brick walls separated by a 2-inch airspace) is greater than a single wall of equivalent mass (e.g., homogeneous 8-inch brick wall). Other factors could include the spacing of the studs, the gauge of the studs, the amount of insulation, and even the number of screws used. Vents can be carefully placed and fitted with elbow joints, so the sound doesn't pass through one room to the next.

It's important to seal any penetrations like piping and ductwork with a non-hardening sealant. This helps to prevent acoustic leakage which reduces the performance of the wall.

While sound can travel through air pockets like ductwork and stud and ceiling joist cavities, it can also be conducted along studs, joists, pipes, concrete, and glass. Sound vibration uses a rigid surface to travel. Adding resiliency can be another way to improve acoustical performance. Examples include the use of resilient channels, resilient clips with a rubber element, or even adding springs to a ceiling system.

A room's walls may have two of the exact same ratings but could be constructed differently. Because of that, the perceived noise to a human might be different. It's important to pay attention to construction details to get the desired result.

5. STC Testing: Field versus Lab

There are two ways acoustic isolation ratings can be tested: in the field or in the lab. The STC rating is the result of laboratory acoustical testing. Field testing results include ASTC, NIC, or NNIC. The lab and field test methods are similar, but there are variations. Building codes typically allow for a 5-point tolerance between the lab-tested STC and field-measured rating; however, studies have shown that even in well-built and sealed installations the difference between the lab and field rating is highly dependent upon the type of assembly.

Lab testing is conducted in a highly controlled environment designed to minimize flanking and leakage paths. Acoustic labs have extremely low ambient noise levels, and they are temperature and humidity controlled. Product manufacturers typically rely on lab testing to acquire STC ratings and supporting data. As noted earlier, this allows for the comparison of performance between products. It also gives designers an idea of what performance will be in the field.

Field testing may result in a slightly different rating. This can be attributed to the real-world conditions of the test environment. This can include flanking paths not associated with laboratory tests, differences in construction methods between the field and lab, and variations in room volume and geometry. It may also be in part attributable to the amount of acoustic absorption in the receiving space. In either case, it is advised to design critical partitions or floor/ceiling assemblies with a margin of safety that considers the expected in-field performance.

Field testing can also be used as a quality assurance tool. It helps to demonstrate that construction complies with the design goals for the project. It is also sometimes required to demonstrate compliance with building codes.

6. Why Add-On Panels Don't Improve STC Ratings

Many people ask if adding acoustic panels will make their neighbors quieter. Acoustic panels provide sound absorption which is different from sound isolation. They prevent sound from reflecting off a wall back into the same room. As these are porous, lightweight materials, they are not very good at blocking sound from traveling from one space into another. Because of this, adding on acoustic panels does not generally improve an STC rating. While panels don't prevent sound from going into another room, they can certainly improve sound quality in an enclosed space by controlling sound absorption and reverberation.

Outlook for Acoustic Control

Acoustic control is becoming increasingly essential to human health, the ability to concentrate on important tasks, and managing stress. Acoustic control is now a major consideration in sustainable design projects. Not surprisingly, recent additions to the LEED certification program directly address the importance of acoustics and noise control to the overall health and well-being of building occupants and the surrounding environment. As architects and building owners recognize the significance of environmental sound control, an understanding and focus on acoustic solutions and ratings will be essential. For manufacturers who can provide documented and effective acoustical products, the opportunity for growth is unlimited.

Intertek: Your Acoustical Testing Partner

If you need STC testing or another acoustical test, contact Intertek. We have been performing acoustical tests on building products since 1997. Intertek is on the cutting edge of technology and information pertaining to acoustics. We are involved with ASTM in writing the acoustic testing standards and will test to see if your products are meeting your requirements. Contact us to learn more about how we can help or check out our additional FAQs on acoustical testing.

For more education on acoustics, view our acoustic webinar series: a three-part series that discusses architectural acoustics, sound testing for specific product categories, noise sources that can affect acoustical performance, acoustical analysis, and much more.

Jennifer Levins,

Building & Construction, Regional Manager

Jennifer has over 15 years of experience working in architectural acoustics. She's completed acoustic field-testing programs throughout the country for general contractors, architects, developers, and manufacturers. She draws on that role in her current position as a Regional Manager for Intertek in Kent, WA. Jennifer studied acoustics at the University of Hartford and holds a bachelor's degree in engineering.