Enhanced Inspection. Smarter Decisions.

In the complex world of offshore oil and gas production, stakeholders are continually striving to ensure economic production levels, reliability and safety, as well as drive down operating costs. Ageing equipment that requires accurate condition assessments; detailed inspection and maintenance data needed to meet industry regulations; and equipment complexity are just some of the challenges facing OEMs, drilling contractors and operators around the world.

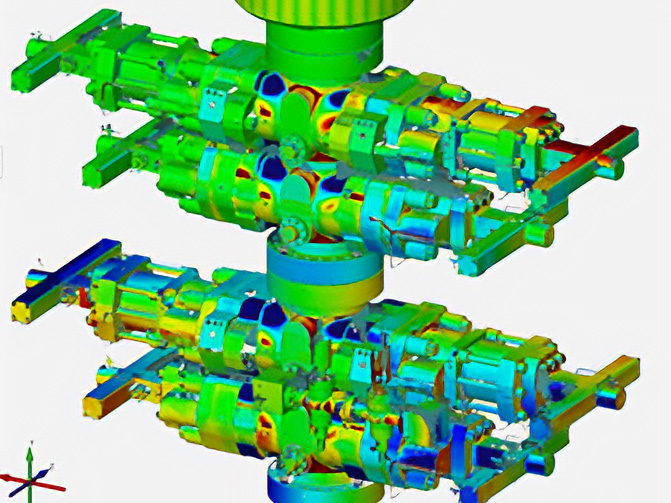

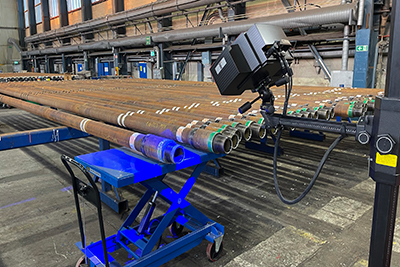

Intertek DeepView3D is an advanced and sustainable inspection technology that combines inspection expertise, robotics, laser scanning and advanced non-destructive testing for optimal condition-based maintenance and the development of digital twin programs, This precise inspection methodology baselines equipment and assesses their condition while optimizing production and maintenance workflows.

Providing a deep view of asset condition while setting the new standard for digital mechanical integrity data and condition assessment, Intertek’s DeepView3D solution helps customers establish condition-based maintenance programs that track and ensure equipment safety and reliability. Our clients see the DeepView3D solution as part of a CBM (Condition Based Maintenance) program where, over time, they look at opportunities to move away from time-based maintenance and over to condition based maintenance programs.

Technology

Delivered by industry-leading experts, our DeepView3D inspection technology combines robotics, laser scanning and advanced non-destructive testing.

OEMs

Original Equipment Manufacturers see valuable benefits such as digital documentation of baseline equipment conditions, asset condition tracking and comparisons over time, and much more.

Equipment Owners

Equipment owners and engineering groups utilize Intertek’s workflows and advanced inspection technology to move ahead of the failure curve and transition from overhaul and preventive programs to predictive maintenance plans.

Operators

Our technology provides perpetual records of critical assets, such as BOPs, that interface with clients’ data management systems to analyze dimensional changes, performance, and behaviors that might impact the integrity of well campaigns.

Applications

The DeepView3D methodology is applicable to many industries, especially the energy industry. Our advanced techniques can be used to assess BOPs, drilling systems, drawworks, mud pumps, top drives and structures.

Complementary Services

Our expert solutions also include mechanical integrity evaluations, stress analysis, Aware asset performance management software, corrosion and materials evaluations, design review and much more.

Key Benefits

Intertek DeepView3D provides a range of benefits for OEMs, drilling contractors and operators alike. Some of these benefits include:

- Enhanced equipment safety and reliability

- Meeting regulatory requirements

- Auditable digital records of equipment condition

- Asset condition tracking and comparisons over time

- Reductions in costs, time and manpower

- HSE improvements

- Big data capture and analysis

- Support for fitness-for-service and remaining useful life (RUL) decisions

- Digital documentation of baseline equipment condition